Introduction

“DuPont connector” is a vernacular term which refers to a number of different types of 0.1″ pitch connector. They feature black plastic housings which retain contacts with fingers built into the housing body. All are very similar in appearance but vary significantly in quality and price.

There are various other names often attached to these, such as “TYU Connector” or “JWT Connector” (drop a comment if you know of another). These are acronyms for some of the many Chinese manufacturers, sometimes physically moulded into the product.

In some cases “DuPont connector” may refer to unrelated connector types which vaguely resemble the original design, however are significantly different in detail. Chinese reproductions of Molex SL / AMPMODU MTE and Molex CGrid III are some examples. On this page I’ll be sticking to the original series, and close look-a-likes.

Contents

- Mini-PV – The original “DuPont” connector (rarely used by hobbyists)

- Harwin M20 “DuPont” clone type (most common type used by hobbyists)

- Mixing Mini-PV and M20 contacts and housings

- Berg/DuPont “Maxi-PV”

Mini-PV – (Amphenol ICC – formerly FCI, formerly DuPont Connector Systems, formerly Berg)

Mini-PV was the first 0.1″ (2.54mm pitch) design of this type likely introduced in the 1950s by Berg Connectors which appears to have spent much of its life as a division of E. I. du Pont de Nemours and Company. Its contact measures 1.25mm square and features an elaborate bi-metallic design with a brass contact body and a beryllium alloy spring. As the heading suggests it has changed hands a few times since then.

The original Mini-PV family is still manufactured today by Amphenol in the USA, but is a fairly premium product which is not marketed for hobbyist use, and is priced accordingly, as one would expect for a product which has been produced by Uncle Sam to same specification for more than 70 years. In subsequent decades its design as been copied and altered by other parties.

I found Amphenol ICC’s website quite difficult to navigate, with catalogues incomplete, publicly available datasheets and documentation at best sporadic, and virtually non-existent for tooling. On this page I have summarised the parts which may be of interest to hobbyists who aren’t on a tight budget.

The most interesting feature is variable spring tension. I use “Ultra-high” types (48257-000LF) as it is rare that I build anything requiring more than 6-8 positions in one connector, and the higher disconnection force eliminates the need for latching.

In practice these should have been labelled “low”, “medium” and “high” as the “standard” type is not standard at all, it is actually a specialty contact which only makes sense in connectors with large numbers of positions.

Spring tension is rated for 1000 mating cycles.

Example part numbers

Numbers in bold can be changed to order connectors with a different number of positions. Note that some don’t correspond to the number of positions, I’ve added a few examples of these to show how to work out the needed part number.

| Housing 1×1 position (quite expensive for some reason?) | 65039-036LF |

| Housing 2×1 position | 65039-035LF |

| Housing 3×1 position | 65039-034LF |

| Housing 1×3 position polarised | 78211-003LF |

| Housing 2×2 position | 65043-035LF |

| Housing 3×2 position | 65043-034LF |

| Polarising blank plug | 65307-001LF |

| Female contact AWG 22-26 (‘ultra high’ mating force, 15µ Gold) | 48257-000LF |

| Female contact AWG 22-26 (‘high’ mating force, 15µ Gold) | 48254-000LF |

| Female contact AWG 22-26 (‘ultra high’ mating force, Tin) | 47750-000LF |

| Female contact AWG 22-26 (‘high mating’ force, Tin) | 47715-000LF |

| Female contact AWG 28-32 (‘high mating’ force, 15µ Gold) | 48254-000LF |

| 36 pin single row snap off header (15µ Gold) | 77311-818-36LF |

| 36 pin single row snap off header (Tin) | 77311-418-36LF |

| 36 pin single row snap off header – long 10mm mating pins (15µ Gold) | 77311-832-36LF |

| 72 pin dual row snap off header (15µ Gold) | 77313-818-72LF |

| 72 pin dual row snap off header (Tin) | 77313-418-72LF |

| 3 position polarised vertical header (15µ Gold) | 69167-103HLF |

| 3 position polarised right angle header (15µ Gold) | 78208-103HLF |

Cut strip / loose piece

The female contact part numbers I’ve listed are for pre-cut (loose piece) packaging. They are considerably cheaper if purchased as “cut strip” (reel packaging) however note that these are designed to be crimped by a “feed through” applicator, which means that cutting them for use in hand tools is quite time consuming.

Part numbers are in the catalogue. Note that distributors such as Mouser and Digi-Key only stock a very limited range of these contacts in “cut strip” form.

Wire-to-wire system

Mini-PV also features a wire-to-wire family. I’ve not been able to find a catalogue which gives an overview of this family. It uses the same female contact as the wire-to-board system, but introduces a male contact and different housings.

The same housing is used for both male and female contacts, with the housings containing male contacts having a shroud permanently latched to it (and rather difficult to remove once fitted) – sold separately. The shrouds latch into the contact opening, not the tabs on the side, same for the mating connector friction latch, so will also latch onto regular unpolarised housings no problem. They latch onto “DuPont” clone housings too.

I found the quality of these to be quite good, comparable to Molex SL (also featuring a high quality wire-to-wire option). Tolerances are tight, and disconnection force is considerable, especially when loaded with ultra high force spring contacts. The dual row types appear to be unique. I’ve not found any other example of a dual row 2.54mm pitch wire-to-wire connector of this style.

If already invested in this system, these are well worth considering however note that 8 positions is the maximum available, and as is always the case with this family, they’re not cheap.

Example part numbers

Numbers in bold can be changed to order connectors with a different number of positions. They are available in single row 2-4 position configurations, and dual row 4-8 position configurations with part number suffixes ranging from 001LF to 003LF for each type.

| Wire-to-wire housing 2×1 position | 67954-001LF |

| Male connector shroud 2×1 position | 67955-001LF |

| Wire-to-wire housing 2×2 position | 68105-001LF |

| Male connector shroud 2×2 position | 68106-001LF |

| Male contact AWG 22-26 (30µ Gold) | 75967-112LF 75967-312LF |

| Male contact AWG 28-32 (30µ Gold) | 75967-111LF 75967-311LF |

| Male contact AWG 22-26 (Tin) | 75653-002LF |

Crimp tools

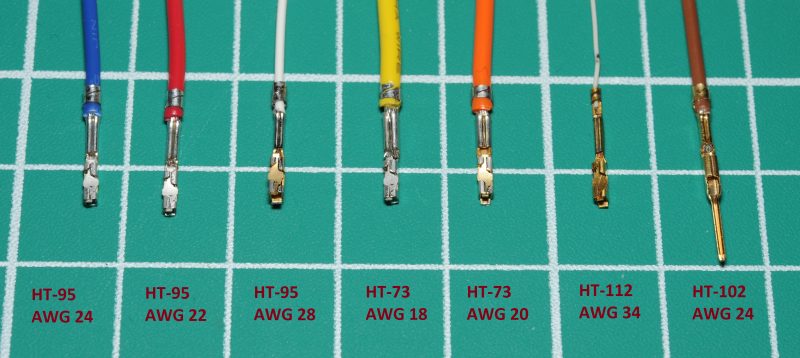

If you can afford to use these connectors, you’ll also be able to afford to buy the appropriate tools to crimp them, even if only second hand – they are well worth it. I have confirmed six types:

- HT-95 (AWG 22-32): The current and most commonly used Mini-PV tool. It’s large and expensive but crimps these contacts to perfection.

- HT-102 (AWG 22-32): Same as the HT-95 but has a modified locator for male contacts.

- HT-73 (AWG 18-20): For ridiculously large wire sizes.

- HT-112 (AWG 34-36): For tiny wire sizes. Tool and contacts are special order only.

- HT-208A (AWG 22-26): Single die hand tool. Discontinued.

- HT-213A (AWG 28-32): Single die hand tool. Also discontinued.

I’ve not been able to work out what the exact use-case for the HT-73 tool is, given that the wires it crimps are too large to fit into Mini-PV housings. Uninsulated single terminations perhaps?

I’ve not ever been able to find an exhaustive list of all of the DuPont crimp tools and accompanying documentation. Some datasheets are available, but aren’t necessarily much help. There are many other HT-xxx tools in addition to what I’ve listed, all for sale on eBay in various quantities and states of repair. Most of these are for the obscure Maxi-PV family but there are many other types too, likely for obscure, largely forgotten former DuPont connector products.

The price of the most commonly used HT-95 tool brand new seems to fluctuate between high and extremely high. I have seen it sold for as little as $800, as high as $1600.

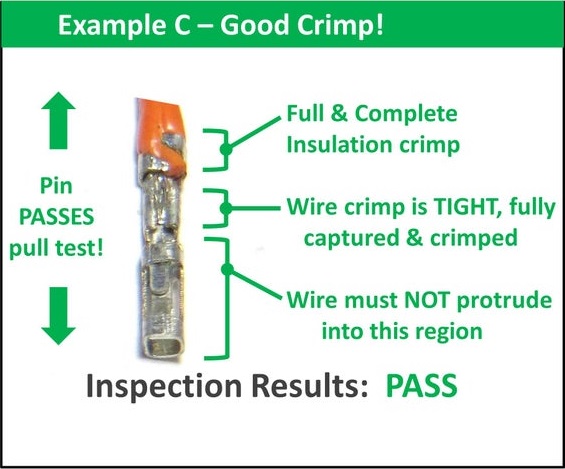

Example crimps

It is possible to crimp AWG 22-26 contacts in the AWG 28-32 die of the HT-95/102 tools however they will “extrude” (elongate) significantly, potentially beyond the end of the housing insulation once inserted.

Old single die tools

I am uncertain as to why DuPont offered two different series of tools for one connector family. The ergonomics of these tools is vastly superior to HT-95/102, but results are tiny bit rougher. They were discontinued decades ago, and may have been offered as a more affordable alternative the tools I mentioned earlier, however I cannot confirm this as it appears that no pricing information remains in the public domain.

If you do buy one, expect to have to do some repair work on it. I had to re-mount the spring and replace the original locator with a 1×1 housing on both of mine.

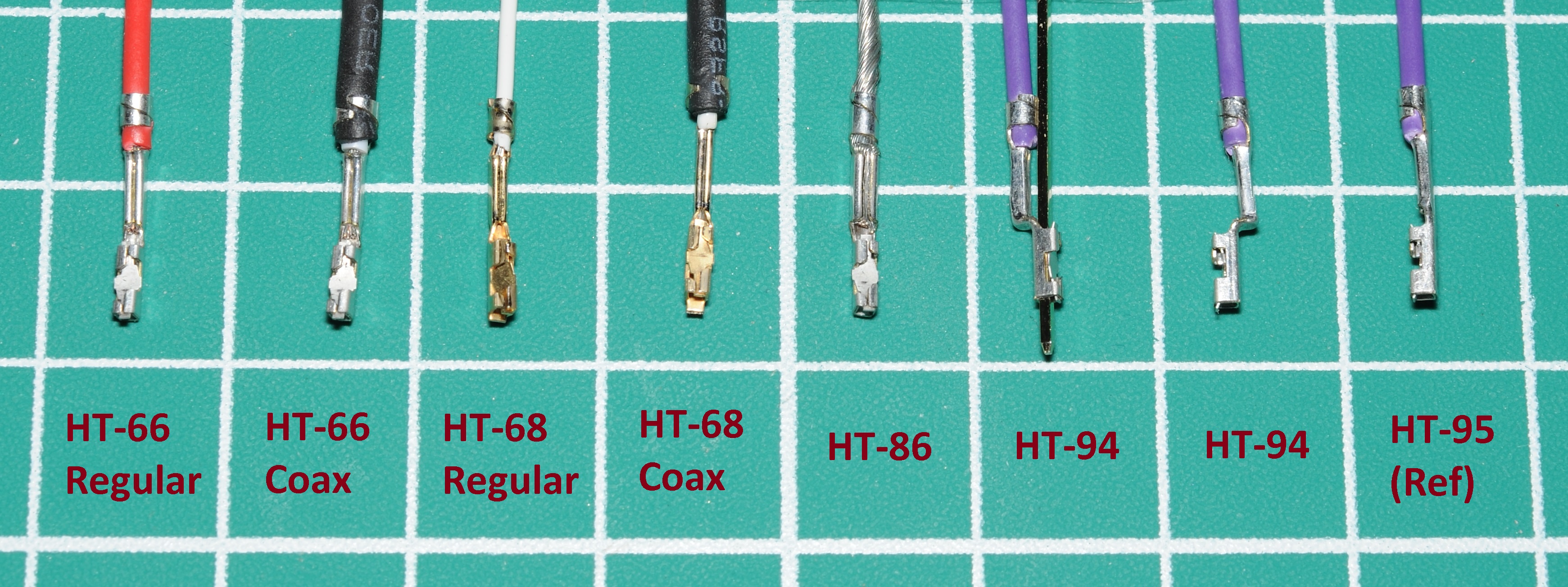

Oddball crimp tools

In addition to the tools detailed above, there are a further 4 specialties:

- HT-66 (AWG 22-26): The locator and right hand die in this tool is the same as that of the AWG 22-26 die in the HT-95. In this respect, it is half of an HT-95, and all of an HT-208. The left hand die is also an AWG 22-26 die however features a significantly larger insulation crimper. It is labelled “COAX INSULATION” implying a particularly large diameter insulation. I am uncertain what the use-case of this larger die is, as crimped contacts do not fit into Mini-PV housings.

- HT-68: (AWG 28-32): This is the companion tool of the HT-66 containing two AWG 28-32 dies. The right hand is the same as the AWG 28-32 die of the HT-95 and HT-213. The left hand is labelled “COAX INSULATION” and crimps wire with the same ridiculous insulation size as the HT-66 is intended for. Once again, use-case unknown.

- HT-86: A bare conductor crimper for AWG 18-20 or 22-26 contacts (works best with 22-26). It has quite a large conductor crimper, around AWG 18-20 but a small adjustable insulation crimper, with the intention of crimping the insulation part onto an AWG 18-20 (ish) bare conductor. Crimping the shield of a coaxial cable into a contact is a likely use-case.

- HT-94 (AWG 22-32): This is the most peculiar crimp tool of the lot. It contains exactly the same dies as the HT-95 but a very different locator which bends an offset into the contact while crimping, allowing crimped contacts to be stacked on top of one another. I am uncertain as to how these would be used in practice as the distortion of the contact means they don’t fit into Mini-PV housings.

Example crimps

Other crimp tools

- HT-110 (AWG 18-20): For male contacts in this size range. As with all these large sized crimps, they wouldn’t fit into standard housings, so I’m unsure of its use-case. It’s too large for clone contacts, and the original types it’s designed for aren’t stocked by any distributors. Would make a good doorstop if you can pick it up for a couple of bucks.

- HT-114: A very basic low cost scissor action tool. It appears to be quite uncommon.

- SP1552 (AWG 22-24?): Appears to be a well designed counterfeit tool from the early 2000s. Often seen cheaply on eBay. Insulation crimp is a suspect oval shape (it should be circular) and conductor crimp is looser than HT-xx tools. For the money, worth looking at nonetheless.

Crimping with unofficial tools

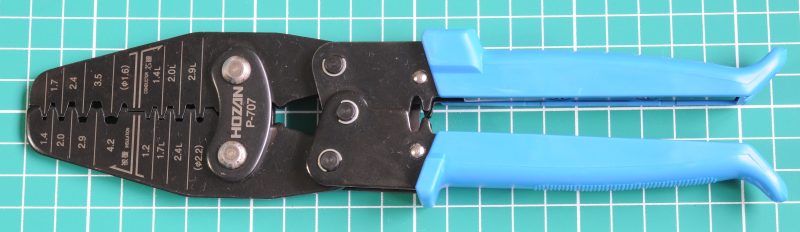

The Hozan P-707 crimps these to near perfection, although it takes three actions to get the job done. It’s quite possible that an HT-95 tool may be able to be obtained second hand for similar or less money.

Any other tools which crimps “M20” clone types will also handle these to varying degrees. The IWISS SN-025 does fairly well however is a little light on the conductor crimp.

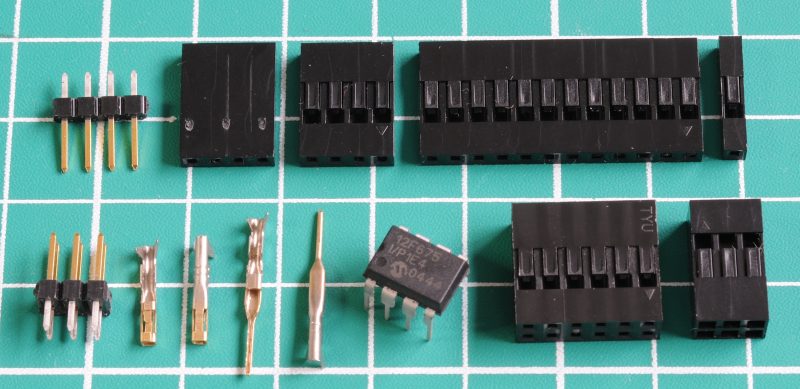

M20 – “DuPont” clone (Harwin, and many others)

“DuPont connector” generally refers to these. Its contacts are typically bent from a single piece of stamped brass into a box shape around 1.6mm square. Unlike Mini-PV which has 4 different contact sizes, and 3 different spring tensions this type has just one single size, and one spring tension (loose) – covering AWG 22-28 wire sizes, and is available in either Tin or “gold flash” plating (a few atoms thick).

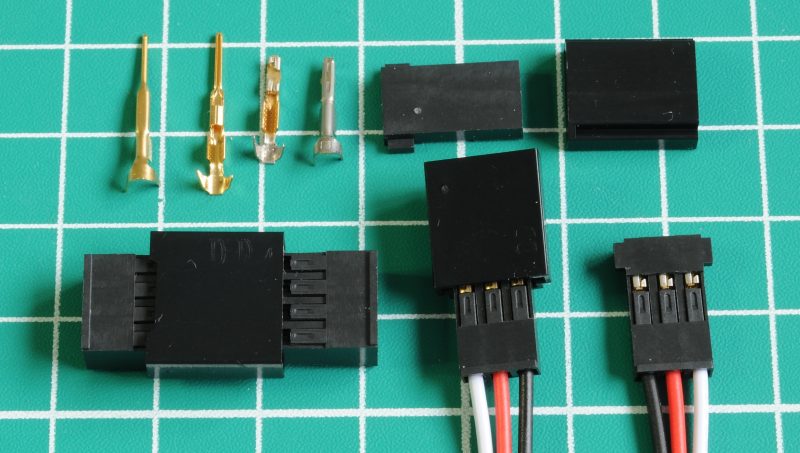

This connector family has a significantly smaller range of components than the Mini-PV family that inspired it, with product being limited to unpolarised housings, pin headers and female contacts. The picture above is basically the lot. Male contacts are available, but are not an official offering from established manufacturers or orderable from well-known suppliers.

There are some examples of unconventional “DuPont” type connector products, for instance 3 position types are commonly found in various polarised varieties for RC servo use, they’re similar to the Mini-PV wire-to-wire type. Toby Electronics (UK) also sell a range of polarised receptacles under their own brand name, once again similar to the Mini-PV type polarised connectors.

I first saw these copycat connectors in the late 1990s. I’ve not yet seen any equipment from prior years containing them.

Harwin are the only well known connector manufacturer producing this type I’ve ever been able to identify. Could they be the creator of the first “DuPont” clones? Today these connectors are made in countless factories in mainland China, comprising the bulk of what is for sale online, many of which are particularly poor quality.

Regardless of where they are made, and by whom, all non Mini-PV types are largely identical to Harwin’s “M20” design, with variation limited to quality of materials, and accuracy of stamping, bending, moulding and plating. As such there is no purpose in listing individual manufacturers of this type.

I used these a lot a decade and more ago however now I only use them for prototypes. Even with the best quality Harwin contacts, spring tension is poor, less than the lowest tension Mini-PV type, and with brass not being a particularly “springy” material, are only good for a handful of mating cycles before they may need to be re-tensioned.

For connections which are frequently mated/unmated and need to be dependable, the money saved isn’t worth the extra hassle created by the poor contact durability (in my opinion), also considering that genuine Mini-PV connectors are reasonably priced when purchased in bulk.

Example part numbers (Harwin):

Numbers in bold can be changed to order connectors with a different number of positions.

| Housing 1×1 position | M20-1060100 |

| Housing 2×1 position | M20-1060200 |

| Housing 3×1 position | M20-1060300 |

| Housing 2×2 position | M20-1070200 |

| Housing 3×2 position | M20-1070300 |

| Polarising blank plug | M20-003 |

| Female contact (Gold flash) | M20-1180042 |

| Female contact (Tin) | M20-1180046 |

| 36 pin single row snap off header (Gold flash) | M20-9993645 |

| 36 pin single row snap off header (Tin) | M20-9993646 |

| 36 pin single row snap off header, right angle (Gold flash) | M20-9963645 |

| 36 pin single row snap off header, right angle (Tin) | M20-9963646 |

| 72 pin dual row snap off header (Gold flash) | M20-9983645 |

| 72 pin dual row snap off header (Tin) | M20-9983646 |

| 72 pin dual row snap off header, right angle (Gold flash) | M20-9953645 |

| 72 pin dual row snap off header, right angle (Tin) | M20-9953646 |

The male contact pictured above is not manufactured by Harwin. Mine were purchased from a Chinese seller on eBay.

Popular crimping techniques

The majority of all hand crimping of these contacts by hobbyists is done by an SN-28B or similar tool. If you’re happy with a crimp like the one depicted above – my experimentation found you can save yourself $20 by using a hammer.

Official tooling

Factory crimping of this type is done mostly by Chinese designed applicators fitted with dies which produce “reasonable” results (not quite correct, but fairly close).

In the years since I first published this page, I’ve only been able to identify one hand tool which is specifically designed for these contacts and crimps to spec (thanks to a tip from a reader). The Mini-PV hand tools crimp these contacts very well however aren’t designed for them, and need to be specifically adjusted to do so.

When the Z20-320 is combined with a pre-set length wire stripper i.e. Knipex 121202 the result is a very fast, easy and consistent termination process.

There was an earlier Harwin branded M20 crimp tool tool marked “Z1015-00”, from a different manufacturer (Wezag) – an even less likely item to find for sale.

Using Mini-PV tools with clone contacts

Historic readers of my site may have observed that I spent quite a few years plugging the use of Berg/DuPont (now Amphenol) tools for crimping clone type contacts. I potentially may have doubled, even tripled the second hand price of these tools by doing so. Today I have pulled back from this recommendation a little.

The main problem with using these tools is that clone contacts are quite loose and don’t sit in the locator very well. As a result of this it’s very easy to have a contact swing to one side during crimping. If the jaw is closed with a misaligned contact the anvil will snap off, at which point the tool is finished. It is possible to replace them however the cost (~$100) of a single anvil is typically higher than the second hand price of an entire tool.

Despite that, tools HT-66, HT-68, HT-95, HT-102, HT-208 and HT-213 are respectable for crimping clone contacts, and if you have already invested in one, you made a good choice, so long as you don’t break it. The others I have mentioned require genuine contacts and are of no use here.

For tools HT-66, HT-68, HT-95 and HT-102 – the locator needs to slide back a little further. This can be achieved by either removing the rubber O-Rings pictured, or loosening the hex grub screws retaining the locator pins. Failing to do so will potentially crush the mating end of the contact.

If you are making this modification, tape the O-Rings to the inside of the handle, as you, or whoever owns it next may want to revert it back to its original configuration. Removing the O-Rings is not a preferable method as you are likely to damage them in the process.

For tools HT-208 and HT-213, it’s more difficult. A 1×1 clone housing must be cut down to fit into the space occupied by the original locator, then the fixing plate must be packed up a little. I used a cut out piece of soft drink bottle to achieve this. The added bonus is that in this case you’ll end up with a tool that crimps either gender of contact, and using this arrangement it is not possible for the contact to misalign during crimping.

I wouldn’t recommend HT-68 and HT-213 or the AWG 28-32 die of the HT-95/102 for clone contacts as much as they crimp down to a very small size, resulting in extrusion (elongating) of the crimped termination. This is not an issue with genuine parts as a smaller size is used.

HT-86 does work with clone contacts however it’s quite tight to fit them into the locator.

Crimping (properly) with unofficial tools

M20/”DuPont” clones are one of the few light contact family I’ve encountered which generic tools such as SN-28B and PA-09 suck at crimping.

The problem is apparent when we examine the upper half of the crimp jaw. The original tool is clearly cylindrical, whereas the generic is split, with the intention of curling each side around and back down into the wire again, which is most certainly not what we want for this type of contact.

Engineer have recently (2022) released a new tool – the PA-24 which promises to improve on the crappy PA-09. It actually includes cylindrical dies. I have not seen one myself. Even if you do not intend on buying one, at least treat yourself to the above YouTube video.

The Hozan P-707 is an example of a tool which has cylindrical insulation crimpers. It’s been around quite a while and to date still gets the best results for the money, but at $70-80 it’s a little too expensive for most.

There are (as of 2020) a couple of lower cost tools which have dies like this:

Recently marketed tools with cylindrical dies

Above is the IWISS SN-025 which is sold as being for “DuPont” contacts . I’m not entirely sure it is. More about it here.

Below is an example of a cheap tool specifically designed for these contacts (and some others). Read more about it here.

Is it possible to mix Mini-PV and M20 style contacts and housings?

In short, no. Despite looking almost identical to common “DuPont” clones, Mini-PV contacts/housings and clone contacts/housings are surprisingly not interchangeable.

It’s barely visible, but you can make out the differences in the image above. The Mini-PV housing has just a tad less room for the contact, meaning that “DuPont” clones don’t fit. Inserting genuine contacts into clone housings doesn’t work too well either – they’re too loose, don’t latch and easily fall out.

This is a massive pain the wallet in the case of the single position housing – the one you’d want for making high quality jump leads. It’s ludicrously priced at $1.38/ea and 85c/ea in quantities of 100 (Mouser). If unprepared to stomach the cost of single position housings, insulating jump leads with heat-shrink is a cheaper option.

Berg/DuPont “Maxi-PV”

There couldn’t be a “Mini-PV” without there also being a “Maxi-PV” connector family, one that did indeed exist. They are stated to be a 0.125″ (3.18mm) pitch design and are the most obscure connector family I’m aware of.

There are no photographs of them in the public domain (that I could find), nor are there any available to purchase, however there are many Maxi-PV crimp tools for sale on eBay (HT-47/HT-48/HT-49). Clearly they were/are used by somebody, for something or other.

The above drawing is the only clue I could find as to their appearance. Apparently a “Jumbo”, perfectly scaled up version of the Mini-PV connector. Ever seen one? Got one? Drop a comment!

Regarding the HT-73, many standard size and “x-large” size R/C servos have 20 AWG leads but still need a 0.1″ connector to plug into the pin header on the receiver. Nowadays they usually have Tyu crimp terminals (which are better quality of 0.1 terminal than the M20 style) inside those connectors but I have seen servo extensions from 15 years ago from JR Propo that had actual Mini-PV terminals inside the housing and presumably JR were using them on their servos as well. Likely other servo manufacturers were using them on their larger servos with 20 AWG wire as well. The housings are specific to R/C stuff (though generally compatible with generic housings) so they probably were designed to fit 20 AWG wire in the housing.

Have you ever managed to fit crimped AWG 20 wire into housings? The thing that has me scratching my head is that it states in the HT-73 manual that the maximum wire O.D. size for Mini-Latch housings is 1.62mm, and AWG 20 is usually 1.8mm, AWG 18 even bigger, and the tool is designed for these sizes, which it explicitly says you can’t use with Mini-PV connectors.

So that leaves really the only possible use case is crimping terminations which aren’t used with housings. Nothing else is suggested in the manual. Quite an odd use-case I’d have thought. Even stranger, there’s an AWG 18 male contact too (75967-113LF).

I have into JR-Propo style servo connector housings (with some coaxing) but not into generic “dupont” type housings. they are similar but not identical to generic housings. However the back end is a little thinker, and they have a 45 degree bevel on one corner that JR Propo R/C gear use for polarization (not really necessary because signal and ground are on the sides with positive in the center of these three position connectors) Most RC gear do not actually utilize this polarization feature but the JR style housings remain the standard for some reason. I have seen these housings in versions for actual Mini-PV, for generic harwin type terminals as well as “TYU” type terminals (which are different than the Harwin terminals and NOT interchangeable with harwin compatible housings) and currently the most common terminals seen on RC servos, though extensions continue to mostly use harwin terminals). Futaba also uses their own terminal type that I have not been able to identify which resembles a scaled up milli-grid terminal.

There are some detailed pictures of these housings here:

http://www.hansenhobbies.com/products/connectors/servoconnectors/

At first glance they seem to be generic harwin housings but on closer inspection there are differences, the latch for example is a bit different even though these ones are made to be used with M20 terminals.

Example of a TYU (Tarng yu enterprises) JR style housing vs a Mini-PV in a JR style housing.

https://www.helifreak.com/showthread.php?p=7355227#post7390823

For whatever reason, way back in the day the powers that be decided that R/C needed an almost identical to generic Mini-PV connector, but not quite and it has stuck even though generic housings would work just fine with most R/C equipment in use today because almost nobody uses the polarization feature anymore.

If you remove the locator on the HT-95 is it possible to do male pins with it? I’m assuming it is but not as easily as having the HT-102 due to having to line the pin up manually with no locater. Or is it possible to modify the locator on the 95 to do male pins also?

I’ve got a HT-95 for female pins, but it’d be nice to do the male without having to search around for an HT-102. Thanks for any info!

Yes. It will work fine. The dies are identical across the two tools.

It’d probably be easier to try source an HT-208/213 and modify it for male contacts (easy) than trying to find an HT-102.

Yea, the HT-102s seem to be in short supply whereas the HT-208/213s are a bit more plentiful it appears. I’ll look into going that direction, thanks!

Mine both have this modification:

http://techmattmillman.s3.dualstack.us-east-1.amazonaws.com/wp-content/uploads/2015/06/crimpmale.jpg

Basically it’s a cut down 1×1 housing where the original locator was, and I’ve cut out a bit of orange juice bottle to pack the fixing plate – which needs to be a little higher to secure the housing correctly.

Thanks!

I’ll be hunting for a decent deal on some 208s in the next few weeks I think.

The HT-94 may also take male contacts. I’ve got one on order at present. I’ll put some info about it up here if it’s of any use.

I did some looking around about the HT94 and all I could find without having one is that it “makes stackable contacts from standard Mini PV contacts” (http://www.foehrenbach.be/Tool=HT94+158)

Not quite sure what a stackable contact is, so it’ll be interesting to see when you get it in. The holder does look like it can accommodate the female and maybe the male pins with the hole in the back like the older Molex contact holders.

You’ve been down the same dead-end rabbit hole as me. My current theory is that “stackables” refers to the apparently undocumented wire-to-wire system. If this is true then I would expect the HT-94 to be an HT-95 with a unisex locator like in the HT-73, accepting either gender of genuine Mini-PV contact (clones are too fat).

I actually ended up emailing the folks over at Foehrenbach and got a response back on the HT94s –

“When you take a standard mini-pv contact and crimp it with the HT94, then the wire is not only crimped on the contact, but in the same operation, the contacts is bend.

The contact is bend in a way that the wire is no longer in the same line as the box of the contact.

It is very rare..”

I’m picturing it doing an offset on the insulation and wire crimp from the contact end maybe.

That is really interesting, also interesting is that for such an unusual use-case, they come up for sale quite often. I can’t wait to see it 😉

Do you by chance have a “how to” with a bit more detail and some further pics on this mod allowing male pins to be crimped on the HT-208? the HT-102 seems to rarely come up for sale used. Thanks for putting all this info out, such a great resource.

I understand “ if it seems too good to be true” but I just came across what I think is a very good deal for DuPont / Berg crimp tool.

I originally saw it on eBay, added it to my watchlist and received an offer from the seller to buy it for $21.50 delivered.

https://www.ebay.com/itm/FCI-SP1552-Crimping-Tool-22-24-AWG/360409694322?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649

It arrived brand new in box, with a 04/2000 date code

The seller also has a website where it looks like he has nearly 300 available for sale, but at $99, not $29 like his eBay store

https://www.mavin.com/store.php/electronics-components/fci-crimping-tool-sp1552

It has the wire gate and contact retainer and looks very well made with respect to the die shape and finish.

I haven’t tried running some contacts thru the tool yet, but I will try SL and DuPont style.

Zero affiliation with the seller, but just wanted to share.

That is one of the most interesting tools I’ve been made aware of as of late. I don’t think it’s genuine. The insulation die doesn’t close to a circle, also it would be AWG 22-26 not 22-24.

Logo and font is correct for that period but a bit fishy – it’s overly large, has the company name text on it which is a bit odd. I have a box with that exact logo and text on it but never seen it on a tool. The silkscreening on the handle is also suspect – very common on Chinese tools but connector manufacturer tools typically don’t do this because it wears off quickly in production use.

There aren’t any search hits from typical distributors of FCI tools either, whereas all of the other (even discontinued) tools from this period do still turn up results. I wonder where it came from and who the target market was…

The conductor crimp does look to be quite good, and, it has a locator. Never seen anything like it. Send me an image of the result once you try it out.

“The Hozan P-707 crimps these to near perfection, although it takes three actions to get the job done.”

This is a bit confusing to me – I understand there are two actions (one to crimp the conductor and one to crimp the insulator)… so where is the third action required?

One on the insulation, two on the conductor because the conductor dies aren’t long enough for these.

Based on my previous comments, I finally decided to start collecting the tools for these guys (I still like SL though and use that for most stuff). I guess mostly from the ‘neat tools to collect’ side of things. Unfortunately my HT95s that are in pretty good shape otherwise came with a cracked bottom wire crimp die on the 32-36AWG side; pictures didn’t clearly show it up, but I should of asked for more closeups, my fault. Oh well, I got a good partial refund and since I’m mostly using 24 or so gauge wire it’s not a big deal currently.

I did find a very nice set of HT-104s that I can’t find any info on; it has the same part numbers for the die holders as the HT-95s and the same wire gauge guides and from first look the dies look very similar. The locator also looks very, very similar to the HT-95s. I bought them on a whim since they were pretty cheap and looked almost factory new. I figured worse case I can use them for spare body parts to fix up some ugly crimpers if needed. They are on the way to me now, but figured I’d ask if you had any experience with them. I’ve only been able to find one mention online about using them or the HT-95s to do crimps so I’m hopeful they’ll do female contacts.

Woops, got my numbers all mixed up, the 28-32AWG side is cracked. The 22-26 is just fine on the HT-95s.

Yes, the DuPont tools are quite collectable. I’ve also got HT-66 and HT-86 on the way, whatever those do. The HT-94 did not disappoint: http://techmattmillman.s3.dualstack.us-east-1.amazonaws.com/wp-content/uploads/2021/03/ht94.jpg

Quite interesting actually, when wrapped with heat-shrink you can make very nice stackable jump leads, albeit needing a very long pin, but, a very easy way to make up arbitrary multi-way leads.

Tools aside, I’ve never managed to settle on either PV or SL, they are both very good. SL probably a bit better for wire to wire as the range of housings is better, and contacts cheaper. SL doesn’t have dual row wire to wire however.

Regarding the busted tools, yup, lots of on eBay are cracked. I once purchased one which had a snapped anvil, got a full refund then used the money to buy a new anvil from Mouser.

Do you know where to get the best replacement parts (like anvils) for ht-95 is?

Regarding the HT-104. From what I could see it appears identical to the HT-95 (but may not be?). It’s for a connector family called “Jumbo PV” which appears to use Mini-PV contacts, that are folded over 180 degrees then inserted into a wider, low profile housing (which I’ve never found for sale).

What’s not clear is whether the contacts are folded before or after crimping. If before, then I would expect the locator to be set about 1.5mm higher and closer to the dies. Perhaps you can answer this?

That HT-94 crimp looks very interesting.

I’ll hopefully have the HT-104s next week so we’ll see what that one looks like.

The HT-104 showed up today and besides the locator having a slightly larger pin in it that doesn’t allow my contacts to utilize it, crimps just the same as the HT-95.

https://i.imgur.com/FigcIU3.jpg is a picture of the locator.

If I replace it with the one from the HT-95 it works fine. I’ll try swapping out the bigger pins with the HT-95 BergStik pins and see if that works. I’m assuming to make the contact fit a Jumbo PV housing you’d have to manually bend the contact over.

It sounds like perhaps only the cable end of Jumbo-PV contacts is the same then. At least you got a very nice HT-95 out of it!

Yep, if I replace the locator pins with the BergStik pins from my HT-95, it works almost perfectly. You can push the contact onto the locator too far forward so it mangles the insulation crimp, but it’ll hold just fine if you eyeball it lined up correctly in the die.

Basically makes it an HT-95 with the replaced locator pins, I’ll take it.

You could adjust the position of the locator to fix that

Yep, I found some spare 0.1″ headers that where pretty much close to the replacement length and adjusted the locator and now it’s perfect 🙂 I’ve got basically 2x HT-95s now (minus one 28-32AWG side due to a cracked die on the HT-104 since I moved the good die to my 95). I’m pretty happy now.

I’ll probably still use SL for most stuff because I really like the latching part, but it’s definitely nice to be able to make my own 1 position jumper cables if needed since I seem to always lose those or don’t have the correct gender jumpers.

Plus the tools are just cool to have, which isn’t good for my wallet.

Hi.

First-time listener. First-time caller. I absolutely love this website. Can’t believe I haven’t stumbled upon it before.

I’m on my fourth straight article.

The only contention I have so far is the sentence on this page:

“These are the one and only light contact family I’ve encountered which generic tools such as SN-28B and PA-09 suck at crimping”

I’m still not clear on the meaning. Perhaps I’m reading out of a larger context. These tools suck at crimping *which* connector family?

It’s because I change/update/re-arrange these pages regularly. Sometimes context goes missing 😉 Fixed.

Awesome, thanks!

I’m looking to start using the Mini-PV system. Looking for used crimpers on ebay, at time of writing I can find used HT-66 and HT-68 crimpers for about $40 USD each. Or, I can get an HT-95 for $175-$200. You might not even need the 28-32 AWG range, so could get away with spending just $40 on the HT-6, quite a bargin!

If you only need 22-26, HT-66 is the one. It’s probably my fault the HT-95 is so expensive. They used to change hands for $30-$50 back in 2014 when I first put this page up here 😉

I only just put the HT-66 up here, so get one now before those go up in price.

What about the male contacts for AWG 22? It seems like the only one that is designed to handle those is the HT-102, which is harder to find second hand and is now over $2500 new. (Yikes!)

You could fairly easily modify an HT-208 by replacing the tongue of the original locator with a 1×1 housing. Other than that, yeah, not too easy to get an HT-102 unfortunately. Worth putting a watch on eBay if you really want one, they do come up every now and then.

Here’s something interesting, a “dupont” connector that uses gold plated machined brass pins instead of terminals folded from brass sheet. These are designed as high quality connectors for R/C aircraft and drones. The company that makes these specializes in making high amp barrel connectors for li-ion batteries used in UAVs and e-bikes. The large end of their battery connector lineup uses 8 AWG wire and is rated for 300 amps.

https://www.amainhobbies.com/rcproplus-de254-servo-connector-set-10-rpp-de254-diyp10/p1364716

The stripped wire is inserted into the pin and then clamped in a special tool:

https://www.amainhobbies.com/rcproplus-de254-crimp-application-tool-rpp-de254-crimp/p1364712

Here’s a closeup of the completed connector: The “insulation crimp” is a hollow sleeve that gets a divot pressed into it to secure the wire while the area with the conductor gets crushed in the vice/crimper.

https://www.amainhobbies.com/rcproplus-servo-extension-100mm-rpp-de254-m100f/p1390672

Closeup of the crimped terminals:

https://www.helifreak.com/attachment.php?attachmentid=929833&d=1630186030

I am told they mate fine with standard square pin headers. I guess normal dupont pins don’t have any problem with the round pin on a crimped male terminal so the opposite situation (round female connector on a square male pin) shouldn’t cause any problems either.

Just an FYI the IWISS 1442L has a ratchet mechanism in it something the P-707 doesn’t appear to have (correct me if I’m wrong) so while the jaw is a copy of the Hozan P-707 the tool itself is improved over the original.

I ordered a 1442L just to see what it was like (for $30 I figured why not). Normally I use an HT-95 to crimp and a P-706 to lightly precrimp the insulation so that the exact position of the wire in the terminal can be adjusted before finishing with the HT-95. With three position ribbon wire getting all three crimps lined up with each other exactly is important else the finsihed connector will sit on the end of the wire at a wonky angle.

I now own a IWISS 1442L. It crimps well, much better than other ‘DuPont’ crimp tools found on eBay or Amazon.

I have a 213A which is excellent so now I am looking for a 208A. I will settle for an HT 66 (this is a hobby for me) but I do like the ergonomics of the 213A / 208A.

I also own the Engineer PA-20 and Engineer PAD-11 tools which are fine for many crimps but not, as the article says, for the ‘DuPont’ ones.

Some of the oddball crimp tools like the HT-68 can be used as a source of spare anvils for an actual HT-95 or HT-208 with a broken anvil. they typically sell for much less than an HT-95 or 208 to say nothing of a new replacement anvil.

I was wondering about this. How can you determine what anvils are interchangeable with what tools?

How does the Harwin Z20-230 do on Mini-PV Contacts? It’s nice that unlike Amphenol’s tool, it has dies for both 22-24 and 26-30 AWG (on the new model at least, for yours it seems that it is only 26-28AWG). Due to purchasing restrictions, I can only get new tools, so I was wondering if the Harwin crimper would work well with the superior Amphenol contacts.

I just tried it – it doesn’t work. The insulation crimper is too short. It only crimps the conductor.

You can hold the terminal a little forward and crimp half of the conductor part, then get the insulation, however then you end up with a banana shaped terminal which has to be bent straight again. Wouldn’t be acceptable to me.

I did not quite understand how the Hozan P-707 crimps the wire insulation so neatly if the cutouts in its matrix are clearly not round?

two of them are

Good morning,

I need help identifying and purchasing this connector. I hope you can help me. It comes out of Komatsu heavy construction equipment. The connector housing seems to be unique to Komatsu but not absolutely sure. There are no identifying marks on the plastic connector housing however, the crimp on female terminal has “B2” stamped on its base (see picture).

The spade terminal is 2mm across. I recently ordered GT 150 and GT 280 crimp connectors but the GT 150 is too small to slide onto the spade but fits into the housing but it does not have the correct slot to capture it in the plastic housing. The GT280 does have the correct capture slot but will not fit into the housing. I can send pictures if you send me your email address.

I am hoping that you can help me. Komatsu is no help which is frustrating. Please feel free to call or email me with any questions. My number is 502-553-6895. If you are unable to help could you direct me to someone who can please?

Thank you,

Thank you for this informative page. I am a hobbyist and I have been struggling with those questionable ‘DuPont’ crimps and terrible crimp tools for years.

I really, really hate mashing the connections with those dreadful tools. Then, of course, the crimps are only good for light duty work and certainly not for repeated make/break connections.

For dupont, there is a cheaper clone of the Preciva PR-3254 called TOOZO TZ 4228-B.

I use it on flat 4 and 6 core telephone cable which as 24AWG stranded copper in firm plastic insulation with diameter 0.95mm. The insulation crimp seems to be touching the insulation lightly but not compressing it. Perhaps a slightly larger diameter insulation would be better?

To be cheaper clone than the PR-3254. Quite something. It is already a low quality cheap clone tool as it is!

Looks a bit rough to me.

I don’t know if you’ve seen this before. A pretty good overview of all the different options and part families within this system. Including wire-to-wire

https://cdn.amphenol-cs.com/media/wysiwyg/files/documentation/customerpresentation/pv_productpresentation.pdf

I have seen a similar document. That one is a little better actually. Good find!

Hello,

Thanks for this article, it has been very helpful for me! I want to get more professional crimps on my pins and I will be using the crimpers for Radio Control servo connectors, specifically, the Hansen Hobbies connectors.

So, I recently purchased a used set of Berg HT-95 Crimpers that appeared to be in very good shape and they do indeed look good. However, it appears that somebody installed the the upper wire barrel crimper die reversed and the anvil at the bottom was broken and that part was stuck in inside of the upper wire barrel crimper die. I was able to get the broken part out. But need a replacement (B) side anvil for the wire at the least.

Which leads to my question. Is there a place, except for Ebay, to find a reasonably priced set of dies for the tool, without having to purchase a whole new tool? I believe the Anvils and Crimpers could use a replacement anyways. They definitely look like they have been used.

Alternatively, would is be a better option to purchase a new Harwin Z20-320 crimpers, a little on the expensive side, but much better then new HT95 and HT102 crimpers respectively.

Again, thank you for this article, it has been very informative and has led to me to trying to source the correct tool and get more professional results!

Jason Smith

Meridian, ID

Mouser used to sell replacement dies for 80 bucks. Probably a lot more expensive these days and unlikely to be cheaper than a new tool.

Thanks for the reply, I will take a look at Mouser. The tool is in excellent shape, so it might be worth it to purchase a new set of dies anyway. However, I am searching on Ebay to just purchase another HT-95 that I could take the dies out of and use for parts. Thanks again!

104960-001 is one I bought. Yup. 80 bucks. It’s now a non-stock. I shudder to think what it’d cost these days.

If you need dies for an HT-95 the other “oddball” HT series tools that go for much less than an HT-95 that you can take the die from. Just look at the list above and look for one that has the dies for the AWG you need

Engineer now has a tool specifically for Dupont and other such terminals that need a round insulation die: https://www.engineertools-jp.com/pa24

Called the Engineer PA-24, it has a 1.4mm and 1.8mm round crimp dies. They even list the round dupont type insulation crimp dies as a selling point.

Cheers Atomic. I’ll put a mention of the PA-24 in my list. Good to see a manufacturer actually listened!

Obtained PA-24. If you are using it just for dupont/mini-PV I’d call it unusable because it bends the pins when you crimp the insulation. It also does not crimp as securely as the Hozan P-706. If you are crimping 22-26 AWG wire the 706 has exactly the right die for that and the wire will break before it pulls out (and also it doesn’t bend pins)

It’s a shame because from an ergonomic standpoint the PA-24 is superior to te P-706, it’s much easier to use, it just doesn’t produce very good results.

That said, if you are frustrated by the HT-95’s lack of a wire stop then the insulation crimp die on the PA-24 is much easier to use than the P-706, it’s at the front of the tool and the jaw is smaller. So I will be using is to lightly precrimp the insulation lining it up and finishing in the HT-95 when making servo leads. This is a very specific case though most people aren’t crimping ribbon leads and don’t need to worry about all of the terminals being exactly lined up with each other.

I’m late to this discussion and feel foolish I didn’t see Matt’s great site before my latest crimper purchase. Last year I grabbed the Engineer PA-24 when looking for an inexpensive round insulation die that both looked decently made in photos and I could get next-day. I’ve done a couple of dozen crimps on 24 and 26AWG without any pin bends, or really any other issues. That said I’ve only been running distant cousins of the mini-PV through it, contacts from Adam Tech and Cvilux.

I will /never/ use the bolt cutters on these. I loosened the fit of a ‘generic’ Waldom crimper 15 years ago by using the bolt cutters on it and it just doesn’t seem to be worth applying that kind of torque on a device that you want for smooth crimping. A point for the Engineer is that the pivot looks like it can be tightened, but I don’t want to mess with it.

I landed on this site looking around at options for maybe 16-20AWG. I know people love Anderson Powerpole and it looks inexpensive to get into but I much prefer a crimp that catches the wire housing. What would you say is a good value for infrequent use, Matt? I’m thinking readily available in wire-to-wire, and less important to me for this size, wire-to-board, with a simple (read: inexpensive) tool. Thanks for sharing all this knowledge!

Also the PA-24’s screw cutter works well, you need strong hands to cut an M3 class 12-9 screw but the results are excellent.

That is the only part that caught my attention. I do not presently have anything that cuts M3 screws.

Given the popularity of all these Far East tools I’m surprised that no manufacturer has designed a line of terminals optimized for use in them. Is there any reason that an Iwiss tool can’t produce a gas-tight, tessellated-hexagon crimp aside from the fact that it’s not perfectly matched to the terminals?

Seems pretty obvious to me, but I’m not in the manufacturing trade. Maybe it’s more complicated than I imagine.

If you find the answer, let us all know!

Well, I suppose the answer is that hobbyists either don’t know or don’t care about the finer points while professionals pay for the expensive system tools.

It looks like the Engineer PA-24 might be the answer.

Funnily enough, they seem to exist, sort of. Out of idle curiosity (to see what a “factory” crimp looks like) I took the casings off a cheap chinese m-m jumper wire. While the mating pin looked the same as commonly encountered M20 crimps, the crimp part was different – insulation fins were rectangular, non-staggered and shorter, while conductor fins were about the same length, but less wide (1,5mm or so). Looked like something that could crimp quite nicely with the common m-shaped dies both for insulation and conductor. Never saw anything like those in retail.

The Chinese are very good at making applicator dies for “dupont” contacts. Unfortunately this expertise never makes it into hand tools.

Yeah that’s the TY5081 terminal, they are the standard now for standard and large sized hobby servos. Much better than Harwins because they have a separate spring like Mini-PV, but still not quite as good as Mini-PV

https://www.tyu.com.tw/Templates/att/TY5081-2-3-4.pdf?lng=en

They have standard square housings as well but that PDF is for the hobby servo lineup of housings which are slightly different.

Nobody seems to sell these in less than reels of 10,000 terminals unfortunately.

A note for fans of doing it ghetto style – many of those cheap SN-28B style ratchet tools can now be found with wire EDM cut dies (or, you can buy just the die for $10 or so for the handle that you already have – I used SN-2549 die). I have no idea of benefits or drawbacks of wire EDM over other methods of manufacturing crimp dies for cheap Chinese tools, but what matters is, those dies split lengthwise into 2 halves, one for conductor, one for insulation (there are some holes and metal pins included for alignment). You can take a small round file to the insulation half, and a couple minutes of careful filing later, hey presto, a round die. OK, more oval than round, but still better than the original m-shape.

That is certainly still 100% amateur hour crimping (although hopefully somewhat better than a hammer), but at least there is a way to amend the baffling lack of choice when it comes to cheapo dupont-clone crimpers.

I’ve been stalking eBay, and I keep seeing crimpers of the “HT-68” variety that have a funny looking “box” shaped locator that doesn’t look anything like your photos:

https://i.ebayimg.com/images/g/btEAAOSwGGViNO4s/s-l1600.jpg

Any idea what this is or what’s going on?

Thanks.

There are a number of designs for the locator. That one (may) be an earlier type which had a larger finger pad for the contact loader.

Or it might be a completely different tool that has been mis-labelled. I’d need to see the other side of it.

It came in the mail. You were right, it’s just a different model.

Hi! Great site.

Would you kindly share some more media like photos, or a quick video of adjusting the Berg-FCI tools for use with M20 and other clone contacts?

What’s the best present day tool besides Z20-320 for M20? I dislike that Z20-320 does not have a locator like the Berg-FCI tools, making for slower (as compared to Molex, JST, Berg-FCI, and practically all others with their locator holding or retaining contacts for you. Z80-255 is just fine.

Aha! But the Z20-320 does have a locator and it’s fairly ingenious. The little u on the die can hold the pin when you click to the first position. It’s probably one of the most elegant locators I’ve seen, I only like the Molex SL 63825-8800 locator better.

Is there a way to adjust the anvil pressure? I have an old HT-102, but the crimp feels weak, and the crimped pins do not seat properly in the housing. Is the die just dead and gone, or is there a way to recover the tool? I can’t see any obvious anvil pressure adjustment mechanism.

I’m going to answer my own question! After weeks of digging, I finally found manuals for the HT 49, 95, 101, 102, 110, 119, 217, 234, 250, 251, and 270. (Not all mini-pv tools). And yes, it can be adjusted. Search for foehrenbach HT102 User’s Gude (or similar) to find the manual and instructions.

1) Remove cap screw securing the anvil holder assembly to the hand tool and remove anvil assembly. (The large screw in at the bottom center of the crimp die on the opposite side you would insert the pin from.)

2) Insert a 3/32 Allen wrench into the hole in the adjustable tool holder and into the socket head setscrew. Turn 1/4 turn counterclockwise to unlock the adjusting collar. (The Allen wrench goes straight down into the body of the wrench from above into the hole revealed when the anvil holder assembly was removed.)

3) Close the hand tool lever one click to gain access to the holes in the side of the adjusting collar. Next, insert a pin, approximately 1/16-inch in diameter, into one of the holes in the collar. Rotate the collar about about 5 degrees counterclockwise to increase crimp height (rest of sentence blotted out unforunately.)

4) Install the anvil holder assembly onto the hand tool and tighten the attaching cap screw.

5) Crimp a terminal to the proper size wire and check the wire barrel crimp height of the crimped terminal. If the crimp height is not as specified, remove the anvil holder assembly and turn the adjusting collar an additional 5 degrees. Then reinstall the anvil holder assembly and again check the crimp height. Continue adjusting the crimp height in this manner until the proper crimp height is achieved.

6. Remove the anvil holder assembly and tighten the setscrew clockwise in the adjustable tool holder. Then reinstall the anvil holder assembly and tighten the attaching cap screw.

Note: A bent crimped pin indicates either the pin is getting stuck in the die, or the die is cracked or otherwise damaged.

When trying to source male pins, I discovered the old datasheets list the pins

47793-003 18-20 awg, gold reel

47792-003 22-26 awg, gold reel

47791-003 28-32 awg, gold reel

48117-000 18-20 awg, gold loose

48116-003 22-26 awg, gold loose

48115-003 28-32 awg, gold loose

75653-006 18-20 awg, tin reel

75653-005 22-26 awg, tin reel

75653-004 28-32 awg, tin reel

75653-003 18-20 awg, tin loose

75653-002 22-26 awg, tin loose

75653-001 28-32 awg, tin loose

but on the Amphenol site, there is another series of pins that have the part number 75967-xxxLF, such as the 75967-312LF.

I notice the old pins have a small horizontal flange and are slightly taller in profile when compared to the “new” pin. Although I found one or two references stating that the 75967-xxx pins are for Mini-PV, I could not find any explanation as to why the 75967-xxx pins exist, what their differences are, or any other information explaining why the new part number exists. I couldn’t find any databooks with these part numbers.

Do you have any idea what the 75967 pins are for or why they exist?

Thanks.

…and here I am answering my own question again. I finally figured out on the Amphenol site (after looking at the page many times) that, on the Amphenol website https://www.amphenol-cs.com/product-series/pv-crimp.html , you have to click the blue “part numbers” box on the left column, NOT the plus on the bottom, to see the part numbers. After a long process of elimination, I finally discovered that the 75967 part is made of brass, and the other parts are made of copper. They also mark some parts as preferred.

Do you know what the size o-ring is used on the HT-95/102? The most information I could find was that the inside diameter is 0.070″.

I’m not sure myself. Never replaced one.

Hi Matt,

Thanks for putting together this super-useful info!

I’ve found that Rennsteig (subsidiary of Knipex, the famous German plier maker) have a crimping tool specifically designed for Mini PV connectors:

https://www.rennsteig.com/en/products/detail/61600631.html

The model number is PEW 6 (616 006 3 1), it has an inbuilt locator, and is rated for AWG 26-22.

According to the Rennsteig person I spoke to, it is suitable for crimping the Amphenol part number 48234-002:

https://www.digikey.com/en/products/detail/amphenol-cs-fci/48234-002LF/2665637 (Digikey link)

https://cdn.amphenol-cs.com/media/wysiwyg/files/drawing/47212.pdf (Amphenol specsheet).

What do you think? Is this a suitable alternative to the HT-95?

(The plus I guess is that you can get it new fairly easily, and for cheaper than a new HT-95. A used HT-95 would be cheaper than the PEW 6 – however, I figured it’s hard to tell what condition it would be before you buy one, or if the dies are worn out etc.

I’m still trying to clarify if this tool would also work on the wire-to-wire (i.e. male pins) connectors. Do you think it’s likely to work for those as well? (Even if not officially tested/supported).

Thanks,

Victor

You want to use this with genuine terminals? If so I’d guess it would be OK.

Clone terminals are different and don’t necessarily work with tools designed for the originals.

Correct, my plan is to use this with the genuine Amphenol terminals – I will see if I can order them from Digikey. (This is just for home use, not high volume, so I figured some good quality, highly repeatable connectors would be good).

Do you think it’s worth getting (e.g. USD 400) vs say, trying to find a second-hand HT-95 that is in good condition?

I have bought Rennsteig stuff before, and it seems pretty well made.

My other concern is around the wire-to-wire/male pins – I suppose there’s no way to tell from the photographs of it, if there is any chance it will be able to crimp these?

From your text above, it seems the official HT-95 is for female receptables, whilst the HT-102 is for the male pins.

However, you mentions it’s possible to use the HT-95 to do male pins, if you physically remove the locator, correct?

Is it likely we could do something similar for this crimp tool?

Anything that crimps the female terminal will also crimp the male. I can’t tell you anything about the Rennsteig tool but it is usually possible to remove locators to deal with odd terminals.

I hope you have checked the cost of Mini-PV housings too. They are very good quality but boy are they expensive.

I prefer them for R/C aircraft applications for that reason (quality) they are a league above anything else and a failure means loss of a multi thousand dollar aircraft so totally worth the cost in this case.

Did you already see that one here:

https://cdn.amphenol-cs.com/media/wysiwyg/files/drawing/10162309001.pdf

Still a bit too expensive if you ask me. But I wonder how it does compared to the old berg tools.

Thank you for the great post!

I grabbed a very used HT-95 from eBay for less than $100. What a tool. It’s amazing to see the welding on a tool like this. Everything is smooth and precise.

But I can’t make it work. It’s way more complicated than JST and Molex crimpers. Here is what I did:

1. Pushed the locator forward

2. Pushed the terminal onto the guide pin of “B” die

3. Released the locator

4. Applied the crimp

It came out deformed. The front piece is pushed lower than the tail end by 5mm. No matter what I try, it only deformed the connectors. Have I got a damaged copy? Or am I doing it wrong?

It seems quite finicky to work with. How far onto the guide pin do I need to push the connector? As I understand, the tail end of the terminal should align with the backplane of the die. Or is it something else?

If it’s broken, is it possible to repair for a reasonable money or is it better to try my luck with a different unit?

Thank you

Hi, Matt. I find this page invaluable in my quest to crimp so called “Dupont” terminals and the many variants perfectly. Thanks for all your effort. Do I understand correctly that the HT-95 and HT-102 only crimp one terminal gender each, receptacles and pins, respectfully?

The image from the Instructables tutorial literally made me laugh! Unfortunately, the power of false information on the internet is exponentially greater than accurate information with equal accessibility. People, for goodness sake, please read NASA-STD 8739.4A Change 4.

TYU and JWT are both Taiwanese company, not Chinese.

But I’m really afraid that maybe after a few decades, there’ll be no longer any difference…

left by a Taiwanese engineering postgrad…