Contents

- IWISS SN-28B

- MDPC-X CTX3

- Connector Manufacturer Tools

- Test cable

- Definition of terms

- CTX3 die re-labelling

- Mini-Fit Jr (Molex)

- KK.254 / KK.100 (Molex), and similar types

- Commercial Mate-n-Lok (TE Connectivity, formerly AMP), Disk Drive Power Connection System (Molex)

- Serial ATA Power Connection (Molex, and others)

- Mini-PV (Amphenol, Formerly DuPont), M20 (Harwin)

- Economical Interconnect (TE Connectivity, Formerly AMP)

- Cable sleeving tooling

- SN-28B vs CTX3: My thoughts

Introduction

The ability to make cable assemblies to one’s own exact specification is one of the finest preserves of the dedicated PC modder. Doing so requires a good quality crimp tool (or tools) which are appropriate for the types of connectors in use on modern PCs.

Today we have a cornucopia of affordable Chinese manufactured tools to choose from, some of which are quite good, others, not so much. We also have a bonanza of different connectors and contacts to choose from, ranging from ‘phosphor bronze’ gold plated types from name brands like Molex and TE, to dirt cheap types purchased off eBay, made who-knows-where, out of who-knows-what.

Throughout this page I’ll be looking at two of the most common tools used for PC modding, and how they perform on all of the types of connectors used in PCs. I’ll also be looking at all of the connector manufacturers original tools for all of the relevant types. Tools which I could not have hoped to own back in my relative youth, which I now do own, thanks to the magic of eBay, and a lot of patience waiting for reasonably priced second hand units to come up for sale.

IWISS SN-28B (Not to be confused with unbranded SN-28B’s)

This is one of the cheapest and most common crimp tools used in the PC modding community. There are many lower quality unbranded examples of these. Avoid them. They’re not that much cheaper, and are made to significantly lower standards than IWISS branded tools.

MDPC-X CTX3

This is a tool that I only learned of relatively recently. It appears to have a cult-like following within the PC modding community, with some worshipping its every crimp. A crimp tool achieving such a status is not something I ever expected to find in 5 years of testing and writing about them. As such, it cannot be overlooked. We’ll be examining its crimps in detail.

You’ll notice that it looks rather similar to the IWISS SN-28B. I’ve covered the physical differences in detail on this post.

Connector Manufacturer Tools

In addition to the above, I’ll be looking at all 8 of the relevant crimp tools from the designers of the connectors used in PCs today. These tools are all very expensive (if purchased new) ranging from USD $300 to $1450 at the time of writing.

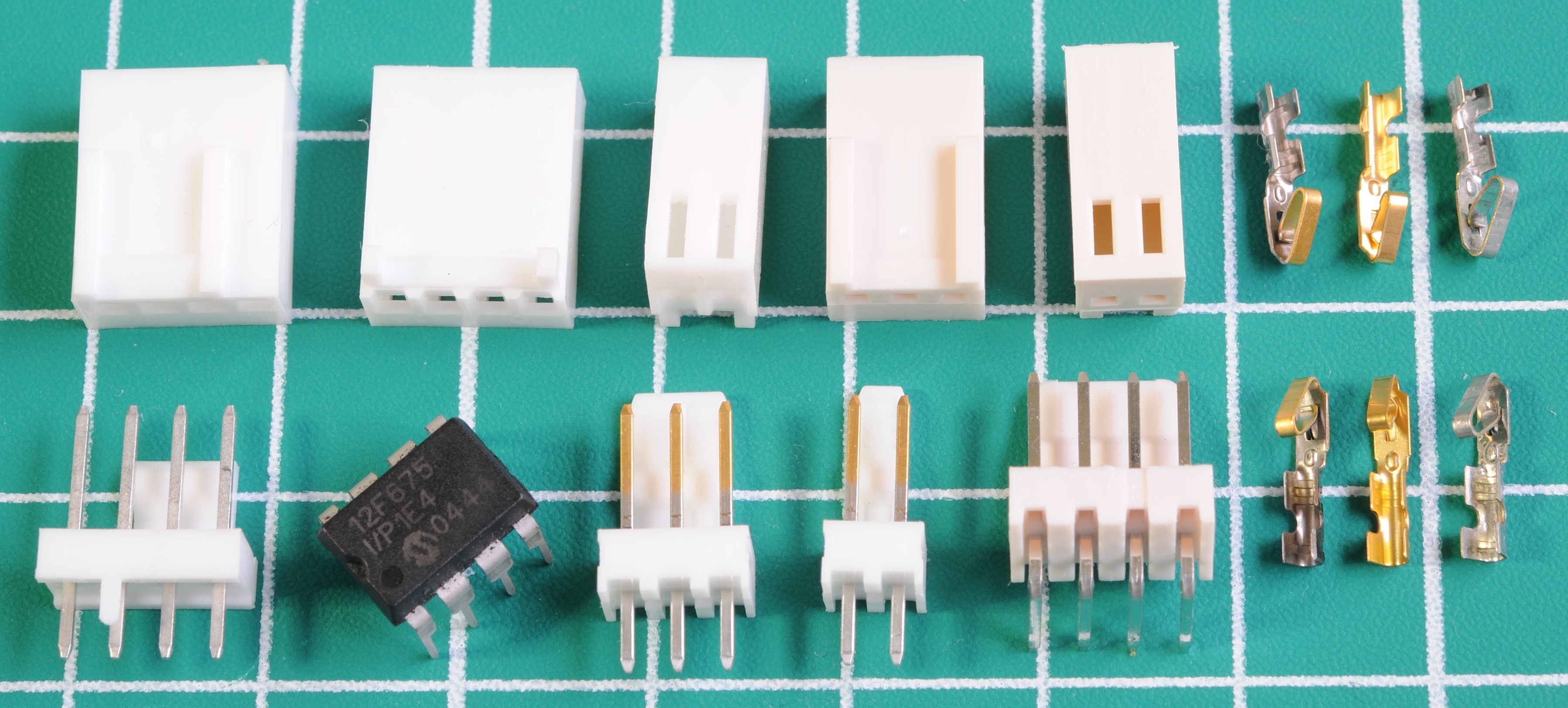

From top, then left to right:

- Molex 63811-7000: Disk Drive Power Connection System (Molex version of the Mate-n-Lok connector) – Top

- Molex 63819-0900: Mini-Fit Jr (Power supply to mainboard connection)

- Molex 63811-8200: KK.100/KK.254 (Fan connections)

- Molex 63823-9900: SATA Power connectors

- Harwin Z20-320: M20 “DuPont” Type (Front panel connections)

- DuPont HT-0095: (Front panel connections)

- TE Connectivity 91512-1: Mate-n-Lok (Disk drive connections)

- TE Connectivity 91556-1: Economical Interconnect (Floppy connector)

I’m not proposing that anyone should purchase any of these, however they do all produce perfect crimps, to the exact specifications of the connector designers, useful for comparing budget tools against.

Test cable

I’ll be using four cable sizes throughout this testing, AWG 24, AWG 22 AWG 20, and AWG 18. The cable I’m using (except AWG 16) is from a known brand (Alpha Wire). The CSA (Cross Sectional Area) on these types is confirmed to be correct, unlike many samples of cable I’ve previously purchased off Amazon and eBay which typically have a smaller CSA than advertised.

Definition of terms

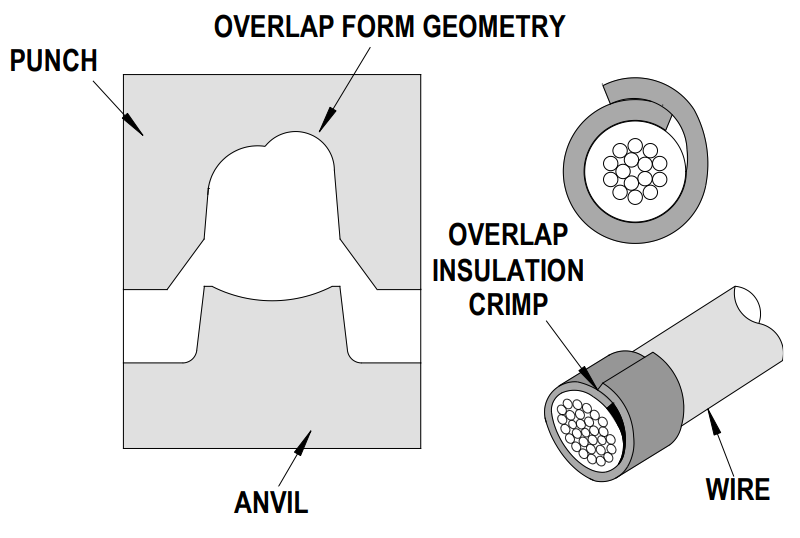

Throughout this page I will use a number of terms from the above image.

CTX3 die re-labelling

As we saw in this post the IWISS SN-28B and the CTX3 are nearly identical tools. The most significant change on the CTX3 was the re-labelling of the dies. This makes a huge difference to the results as we’ll see. MDPC have ground off the original markings from the SN-28B die and re-assigned them (with new markings on the frame) from:

- Large: AWG 18-20

- Medium: AWG 22-20

- Small: AWG 28-24

To:

- Large: AWG 15-17

- Medium: AWG 18-20

- Small: AWG 23-26

This left me with the question: Do I then test the SN-28B “as originally marked” ? or “as CTX3 marked”. I’ve chosen to test it as if it were a CTX3, due the physical similarity of the two tools. I will elaborate more on this decision later on.

Mini-Fit Jr (Molex)

Background

These first appeared in PCs in the late 1990s, having been specified in the new ATX standard. Starting with the 20 position, two row type, which replaced the traditional Molex 90331 type power supply to motherboard connection.

The 4 position two row type was then introduced along side the Intel Pentium 4, quickly snuffing out AMD’s attempt to re-introduce the pre-historic 90331 type connector for supplementary CPU power. Now, they’re all over the place.

Tooling and crimps

A recent tool from Molex is 63819-0900. It’s made by Pressmaster in Sweden and costs around US $300, and is among the cheapest manufacturer original tools I’ll be looking at today. Infuriatingly Molex have discontinued this tool replacing it with two tools: 63819-0901 (AWG 18-24) and 200218-2200 (AWG 16), so you’d now have to spend $600 to get the capability of the single tool I’ve pictured here.

This tool, like all manufacturer tools, has a locator in the rear, which holds the contact during crimping. This makes the crimping process an order of magnitude quicker, easier and more consistent than on budget tools like the CTX3.

For the first set of crimps, I’ve used both AWG 18 and AWG 16 wire, two common sizes. The Molex crimps are bang on as we’d expect. From this angle, the SN-28B and CTX3 both yielded almost identical results, however the Molex tool has a clear difference in that the insulation crimp is “wrapped” instead of being curled over and pieced into the wire.

For the AWG 16 crimps, I’ve used the larger die. In the cases of the SN-28B and the CTX3, I think we can safely disregard the results – Both of those will come out in a light breeze. I’d recommend crimping AWG 16 in the middle die for both of these tools.

On the bottom side, the Molex tool leads, predictably, but we can see how the CTX3 manages to nudge its self ahead of the SN-28B. The SN-28B has left a couple of fatigue points on the base of the insulation crimps. This is can lead to the insulation crimp breaking off under stress. The CTX3 has left a small fatigue point on one side. Does the CTX beat the SN-28B for Mini-Fit Jr then? Not entirely…

We must also consider the conductor crimp dimensions, which are, for AWG 18 (W x H):

- 63819-0900: 1.68 x 1.12mm

- SN-28B: 1.93 x 1.15mm

- CTX3: 1.93 x 1.25mm

In this test the SN-28B beat the CTX3, being slightly closer to spec. This is because MDPC milled a bit off the conductor anvil. They should have left it alone. In the world of crimping, conductor is more important than insulation, so it could be argued that the SN-28B won here, however in the world of PC modding – aesthetics are more important. You decide.

Pull test (AWG 18)

For these tests I’ve used a digital hanging scale to see at what force the wire can be separated from the contact. I did three pulls each of the SN-28B and CTX3 and averaged the results, which were all within 300g of each other. Pull testing is largely pointless on manufacturer tools as in almost all cases either the wire or the contact will break first.

- 63819-0900: Wire broke at 13.2kg

- SN-28B: Clean pull at 10.5kg

- CTX3: Clean pull at 9.1kg

I won’t be doing any further pull testing for now (but may add some more results in future). The story is repeated across other types i.e. extremely good for the manufacturer tool, so-so for the SN-28B, slightly less than so-so for the CTX3 for the reasons just mentioned. I’d rather hang onto the crimps for a bit in-case I need to re-shoot them. Some of the contacts crimped later on are quite expensive.

Insulation crimp “wrapping” vs “piercing”

All Molex tools shown on this page do this. The drawback of piercing the insulation is that it creates a weak point which can lead to tearing under stress. Not an issue for PCs however, as these cables are typically installed and left alone.

KK.254 / KK.100 (Molex), and similar types

Background

These first became common in the early 1990s towards the end of the 486 era when forced CPU cooling became standard. They were commonly found inside power supplies before that if you cared to look.

Despite these being frequently referred to and sold as Molex connectors, it’s uncommon to find true Molex examples. With the sole exception of the 4 position “fan” types, Molex’s housing design is slightly different to the more common type, which is produced by a range of manufacturers.

Tooling and crimps

The contacts, regardless of brand are all of the same design, so looking at Molex’s tool is relevant. The current tool is 63811-8200, again made by Pressmaster Sweden, priced at around $300.

Above is a close-up of the official tool. There is a plastic locator at the rear to hold contacts in place while crimping.

The SN-28B/CTX3 results have been combined due to identical dies (the CTX3 was used). They don’t perform well on these contacts. Both the insulation crimp and the conductor crimp are far too loose, and likely wouldn’t do well in a pull test. Nonetheless, your fan will still spin.

Commercial Mate-n-Lok (TE Connectivity, formerly AMP), Disk Drive Power Connection System (Molex)

Background

This type of connector became the de facto disk drive connection in 1976 owing to Shugart’s decision to use it on their range of floppy drives. It was originally created by AMP as the “Mate-n-Lok” family. At that time Molex offered a competing connector which was incompatible, and ultimately unsuccessful in capturing any of the PC industry market share.

Molex began to manufacture a Mate-n-Lok compatible type in 1983, but for the four position version only. The other types were found here-and-there in older equipment, but not in sufficient numbers for Molex to bother offering their own version.

It’s not much use comparing the crimps of contacts for these connectors in the context of PC modding because it’s actually very unlikely that samples of either of these two manufacturers would ever be encountered. In 25 years of building and dismantling PCs, I’ve never found a Molex original connector (they look distinctly different), and I’ve only found Mate-n-Lok connectors in $5000 Mac Pro’s, and $10,000 Supermicro servers.

Almost everything else is typically an anonymous Chinese designed and manufactured type, comprising practically the entirety of what is for sale within the PC modding scene. The contacts of these vary from manufacturer to manufacturer, are typically different to both TE and Molex types, and don’t fit into their housings. For completeness sake, I’ll include TE/Molex types in the comparison.

Tooling and crimps

There are three different crimp tools for Commercial Mate-n-Lok, however the only one of interest in this context is 91512-1 because it covers AWG 18 wire. For Molex Disk Drive Power connection, there is only one crimp tool, the 63811-7000, which was made be Wezag GmbH, Germany.

In the case of Mate-n-Lok I had to use the larger die on both the SN-28B and the CTX3, as its contacts are too beefy to fit into the smaller middle die. The rest were crimped in the middle die. The SN-28B and the CTX3 both did really well here. There’s no visible difference between SN-28B and CTX3 from this side.

Mate-n-Lok goes all the way up to AWG 14, so I threw one in for demonstration.

From the bottom, we can see a small difference between the SN-28B and the CTX3 as we would expect, however the CTX3’s rounder anvil is of no benefit here, as all of these contacts use thicker material and haven’t ended up with any fatigue points that we saw earlier on Mini-Fit Jr. Being tighter on both crimps, SN-28B result is technically better, but the CTX3’s is a little prettier on the insulation.

It’s amusing to see tool marks from MDPC’s milling machine faithfully transferred onto my Mate-n-Lok contact.

Serial ATA Power Connection (Molex, and others)

Background

This type of connector is born from the Serial ATA specification, and manufactured by a range of big brands. The PC modding community seems to prefer Molex types, convenient, because that’s what I have the tool for.

There is no standard as to the internal structure for Serial ATA power connectors, nor contact design. Because of this you typically cannot mix contacts and housings from different manufacturers.

Tooling and crimps

The current official tool from Molex is 63823-9900, made also by Pressmaster Sweden, priced similarly to the Mini-Fit Jr tool at around US $300.

Due to the dimensions I found it quite hard to crimp these contacts in both the SN-28B and CTX3 tools – the retaining middle section tends to catch on the conductor crimper.

SN-28B and CTX3 both the same from this view, neither have any bell mouth, less than ideal, but not a biggie. The Molex tool wrapped the insulation crimp nicely as we’d expect, and did nice front and back bell mouths on the conductor crimp.

Once again we can see that different anvil shape in action on the SN-28B. The CTX3’s rounder anvil was of no benefit here, with no sign of fatigue from the SN-28B insulation crimp.

Mini-PV (Amphenol, Formerly DuPont), M20 (Harwin)

Background

Connectors resembling these have been used for front panel connections since the dawn of the PC era, however what we use today is not the same the original choices. AMPMODU MOD IV and DuPont Mini-PV are among the oldest 0.1″ grid connectors and were the most common types used in the PC industry the early 1980’s, however other types such as Molex SL, Molex C-Grid III and were also occasionally seen.

In the 1990s the above were mostly done away with, replaced by a cheaper type closely resembling the older DuPont Mini-PV connector. I am not sure who originally came up with these. Harwin are the only name brand I’ve ever been able to associate with this type. Today they are made by many anonymous factories in mainland China and sold cheaply on eBay, and through PC modding re-sellers, as with Mate-n-Lok type connectors, it’s unlikely that one’ll encounter samples from name-brands.

Tools and crimps

Above is a close-up shot of the die from an old DuPont HT-95 tool. At $1450 it is the most expensive tool covered on this page. As can clearly be seen it’s completely different to the small die in the SN-28B/CTX3, with the insulation crimper in an ‘O’ shape. As such the crimps are going to look very different from each other. As it’s quite fiddly to crimp contacts this small, the contacts are held in place on a pin during crimping.

Above is a close-up shot of the die from the Harwin Z20-320 tool. At $460, it’s not cheap. Like most of the Molex tools, it’s made by Pressmaster Sweden. It’s got the same ‘O’ shaped insulation crimper of the HT-95, however is specifically designed for crimping the more common “clone” DuPont type contacts, in that the conductor crimper is a little shorter. Harwin M20 is an example of these. This tool has a nicely designed sliding gate on the rear which holds the contact during crimping, and prevents the wire from being inserted too far into the contact.

In the above crimps the results of SN-28B and CTX3 are combined because MDPC did not modify the SN-28B’s smallest die, the two are identical, and produce identical results (CTX3 was the tool used). Results are clearly quite different from the other tools: Not good. Hardly surprising considering the difference in dies. Also shown here is a crimp from the IWISS SN-025, which crimps these contacts quite well, however AWG 24 is the absolute largest wire size you can get away with.

One rather interesting feature of the original Mini-PV family is that it supports up to AWG 18 wire. It’s difficult to think of a use-case for such large wire on this type of connector, also difficult, is fitting it into the housing once crimped. Because of this the AWG 18-20 “HT-73” tool is mostly a curiosity.

Want good front panel crimps with your CTX3 (or similar) tool?

Get your 1980’s groove on. AMPMODU MOD IV, one of the connector types used for PC front panel connections in days-of-old crimp nicely with these tools, and is still in production. The edges of the housings are a little fatter, so it’s not possible to squeeze two single row housings together onto a dual row header, but that’s messy and unnecessary these days with front panel connections now well standardised.

AMPMODU MOD IV contacts are quite beefy compared to “DuPont” types, and as a result crimp rather well in these tools, however these being around 50 years old, may attract some ridicule. At a pinch, the contacts fit quite well into M20 style clone DuPont housings.

- AMPMODU MOD IV contacts: 1-104480-6 (Mouser)

- AMPMODU MOD IV 10 position (5×2) housing: 87456-5 (Mouser)

Economical Interconnect (TE Connectivity, Formerly AMP)

Background

This type was originally designed by AMP (now TE). The 4 position variety became the de facto standard for 3 ½” floppy drives. Molex did not produce a type like this, but these days, many others do.

No-one installs floppy drives into their PCs anymore (doing so now being largely impossible) however this type is still used as a sundry power connection for small miscellaneous items found inside PCs. For this reason, they’re vaguely worth looking at.

Tools and crimps

The official tool has an ‘O’ type crimp on the insulation, but this is more related to the silly small size of the insulation supporting tabs rather than the shape.

In the case of CTX3, the marketer doesn’t claim this as a supported contact type however, but we’ll look at them anyway.

E.I. Contacts have disappointingly small tabs for the insulation crimp, because of this, dimensions of the corresponding die have to be exactly right to achieve any support at all. The SN-28B and CTX3 results are combined here once again, as they’re identical. The insulation crimper on the smallest die just isn’t right for these. Results are otherwise useable at AWG 20, probably a bit loose on the conductor at AWG 22.

Cable sleeving tooling

When I first saw pictures of the CTX3, I thought that the changes to the die were to accomodate sleeving. It looks as-if I was wrong about that, instead, sleeving isn’t intended to be crimped into the contact. But…

I purchased a pre-made sleeved cable assembly, and the sleeving is crimped into the contact, by some kind of mystery application tooling. Whatever it is, it has an especially large insulation crimper, but quite a small conductor crimper, and one that’s clearly not too far off spec. A sufficiently large ratio that it must have been specifically made for sleeved cable.

Not a combination found on either the CTX3 or the SN-28B. I tried to re-create the crimps I found with the Molex tool. It didn’t do too bad, having the locator made it all quite easy to hold together during the process, but it’s a bit tight on the sleeving. Interesting…

SN-28B vs CTX3: My thoughts

By cutting a little bit of material from the insulation anvil, MDPC have identified a clear improvement over the SN-28B, however it is only of any real benefit on Mini-Fit Jr contacts, admittedly, the most commonly used type in this tool.

The re-labelling of the dies on the CTX3 is the biggest win. The largest die on both tools did a terrible job of even the larger AWG 16 wire, let alone AWG 18, which the factory SN-28B markings recommends. MDPC were spot on with this change. When using Chinese tools, ignore the markings on the die and use the one which gives the tightest crimp, which doesn’t damage the contact or wire during the crimping process.

Unfortunately, by also cutting material from the conductor anvils, the CTX3’s crimps are all looser than that of the SN-28B, which its self are all looser than the manufacturer tools, which of course, crimp to spec. Given that PC modders are also likely to be PC gamers, electrically, they’re going to be pushing their connections to the max, so we want those tighter crimps.

Additionally, PC cable assemblies are not subject to any significant mechanical stress, instead, they’re installed, and left alone, in practical terms eliminating the benefit of the more robust insulation crimp the CTX3 produces.

For practical purposes there’s only a fag paper of difference between the two tools, the same cannot be said of the price.

Further reading

Most of the tools and connector types are covered on this page, where part numbers are specified.

That was very thorough and easy to read, thank you!

It is interesting that the CTX3 actually offered an improvement over the original tool (28B), I am still not sure if that justifies 20€ more in price.

The consensus is that you can use the CTX3 for any cable in the PC, Sata crimps, fan cable crimps, front panel and mini-fit Jr. ones, even if it not perfect, for 50€. Doing things right with a proper tool is cool and all but when the price makes a difference, wouldn’t the investion be worth it?

What I am missing in this test is the SN-025, even though it cannot be bought on Amazon at the moment. In the test you said that it delivered a very good performance on Mini-Fit Jr. terminals, but was lackluster on the other terminals like DuPont or the KK.254 so the CTX3 makes kind of more sense here, or not?

Regarding the SN-025. It’s definitely a heck of a lot better than the CTX3 for DuPont, but for Mini-Fit Jr, It’s really difficult to get the nice crimps I’ve shown on the page where I talk about it. I found it is much easier with a little modification to its die, however this isn’t going to be something for the intended audience of this page I’d think.

Regarding everything else, it’s down to opinion. I’ve presented my findings 😉

well damn. you know what I will simply buy the 28B and the CTX3.. if they are equal I know what to return. sadly the ctx3 isnt on amazon so returning it might be a little bit of a hassle. Thank you very much for your work here, it’s very nice to see enthusiasts show expertise and give info even for niche topics. You definitely helped me here!

Well, after reading most of these and other pages I have ordered the IWISS SN-58B from AliExpress.

Quite reasonably priced at about NZ$31.

Thanks for all the help.

matt.. take a look at this 🙂

https://www.facebook.com/100002147381632/videos/1414905642212708/

Looks nice. Nice big die on the insulation for the sleeving. Does it pass the pull test?

Hi Matt!

Thank you very much for your blog, it contains a lot of useful information! I am trying at the moment to read myself in on the technicalities of PC connectors

I have a question for you: I have used the official Molex Pin extraction tool to get the MiniFit Jr crimps out of the ATX mainboard housing and I found it to work miserably as one has to apply too much force to get the cable out. Do you know by chance if there are other extraction tools on the market which allow to remove the crimp removal more flawlessly?

That would help me a lot

cheers & have a nice day!

I’ve not actually seen this myself. Mine works good, however I only ever use it with genuine terminals. Is that also the case for you?

Do you know why the KK 254 molex crimper has duplicate slots? For instance A=D and B=C

Yes. The dies are the same but the locator behind is different. They’re for an obscure variation of KK.254 with longer contacts and housings.

On my tool I scratched away a bit of the plastic in the locator so I can fit “unofficial” male (https://www.mattmillman.com/info/crimpconnectors/#kk254male) contacts into this side of the tool. It crimps them perfectly.

Ahh okay, got it. I missed that part.

I am tempted to do the same as I cannot get a good crimp with the generic tools for the male version.

Any generic recommendations for this connector soni don’t have to cut at my molex crimper 😅

Hozan P-707 always my go-to without the correct tool, true also for these.

I wouldn’t sweat about slashing up the locator. It’s only 30 bucks for a new one (last time I looked). I can send you high a resolution picture of how mine was modified if interested.

Which slot do you use on the P707 as I also have this.

The locater is £50 -> £60 here 😅

But a picture of how you modified it would be great please.

Sorry, just wondering if you have that image? Not sure if you seen my previous reply ☺

hi mat

Overall, is iwiss sn28B better than CTX3?

Hello Matt,

Do you have any suggestion for a crimping tool for the PCI-SIG new-ish 12VHPWR connection? https://videocardz.com/newz/pcie-gen5-12vhpwr-power-connector-to-feature-150w-300w-450w-and-600w-settings It seems to be a dual row 12-circuit (with six 12V/ground pairs) Molex Micro-Fit 3.0 with four signal connections tacked on. PCI-SIG expects 16AWG to be used to hit 600W total at 12V, but Molex only make/specify Micro-Fit 3.0 to 18AWG (and derate the 12-circuit connector to 5.5A per pin for ~400W with six 12V/ground pairs).

What I don’t want my cables to end up like: https://wccftech.com/atx-3-0-12vhpwr-gen-5-connector-major-safety-risk-using-adapter-confirms-pci-sig/ or https://cultists.network/8815/melting-12vhpwr-connectors/

Kind regards,

Che Lok

Oh my god. What a nightmare. How much do you want to spend?

Thanks for the great blog post Matt. Very helpful and well written.

Do you know what tool to use with a 15 pin male sata connector like the below image?

https://imgur.com/F7wgU6F

I have a number of fan controllers that I want to resleeve.

I have not looked into it, but I am pretty certain molex do not sell these and therefore there is no official tool to crimp them from molex.

So I would give the Hozan P707 a try but no guarantee of course, if I had one on hand I would try it for you!

Where did you get these?

One’s head reels from all the different crimping tools and the huge variety of connectors.

I ended up here while looking for the proper tool for “DuPont” / Harwin M20 and JST-XH connectors. I bought a bundle of two boxes of these connectors of AliExpress and a generic SN-28B was included. It has molded dies and it doesn’t work for either type of connector (mangles the JST-XH badly).

According to your info and some YT videos I have seen, I came to the conclusion that the best inexpensive ratcheting tools are SN-025 for the “DuPont” / Harwin M20 and SN-01BM for JST-XH.

Thank you so much for your article. It is very insightful . I would also like to mod and resleeve a PSU but don’t know how the SATA connectors are called. ( the flat metal tip with 3 prongs ) For a PSU I would like to have split interconnects for more than 1 drive. What do you use for those to crimp down?

When I crimp the sleeve onto the cable it will simply destroy the wires in it. I can’t really recommend it. Used the middle one of CTX3 with AWG17 wire.

Hi,

Has anybody here had much experience with making your own SATA power cables? What parts did you end up buying?

I’ve looking on the Molex website, and I can’t actually find the hand crimping tool mentioned above (Molex part number 63823-9900) – not sure if it’s because it’s been renamed, or there’s something going on with the Molex website?

I did find what I think is the series page for SATA:

https://www.molex.com/en-us/products/connectors/storage-and-memory-connectors/serial-ata-slim-sas-connector-system

and all the parts in that series are here:

https://www.molex.com/en-us/part-list/0305

From what I can tell, the crimp terminals are one of the following:

* Molex 675810000

* Molex 675810010

* Molex 471281002

* Molex 675810011

Does anybody know what the practical difference between the above are?

There’s also a single housing for SATA power:

* Molex 675820000

I can’t find any mention of a “through” style connect, like what MDPC-X sell though:

https://www.cable-sleeving.com/sata-through-connector

(Their product page seems to imply this is an official Molex part though).

And from what I can find, the removal tool is Molex 638132700 – but I can’t find that on the official Molex website either.

Thanks,

Victor

Looks like MDPC have released a new PC crimping tool called the CTX-4

https://www.cable-sleeving.com/crimping-tool

Oh oh. Which rebadged overpriced IWISS tool is this? It already looks familiar!

Looks like a dolled-up SN-2549.

It’s hard to tell with the depth of field in the picture, but it seems like the forward-most die looks like it might have a round anvil for the insulation crimp, which could be an interesting proposition. Likely not worth a doubling in price but interesting nonetheless…

First off, I love your site! You’ve been able to answer so many questions and the info you’ve shared is amazing! That said, I’d like to apologize up front for the upcoming long-winded comment —

I’m curious if you’ve got any new insight into the Nivida 12-pin connector from the 3000-series GPUs since you were last asked about it.

From what I’ve found, they use a semi-proprietary assembly from Astron and while i can find part numbers referenced in a one-off Nvidia doc, I can’t find any information about sourcing the parts or any mentions of the “correct” crimper for the contacts. Based on a message in another forum there may be some overlap with a different Amphenol series (mentioned below) but that could be a very expensive mistake!

The relevant Astron PNs should be A6652212A08 and B6652212A04-H for the contacts and housing respectively, I’m curious if you could find any more information than I have

While I’m on the topic of GPU power connectors, I did a bit of digging on the new 12VHPWR standard and think found some solid info! I’m sure you’re tuned in better than I am and this may not be new info but have noticed some other folks in comments asking about the new spec and wanted to share what I’ve found so far –

From what I could find, the housings for the new “12V VHPWR” connectors are part of (or a derivative of) the Amphenol “Minitek Pwr 3.0” series, now “Minitek Pwr CEM-5” on the Amphenol website. Curiously, this change isn’t reflected in any listings or documentation I could find or on vendor sites (Digikey/Mouser)

The housings are PN 10161719-124GLF

The high-power contacts are PN 10132447-121PLF and take 16-20AWG

The sense/signal contacts are PN 10161952-1210LF and take 28AWG

Crimpers for the contacts are PN 10159387-002 and PN 10163639-001 for the high-power and signal contacts respectively.

Curiously, some of the docs on Amphenol’s site also spec a male high-power contact (PN 10134160-2220LF) and appropriate crimper (PN 10159387-003) for the “CEM-5” line. The existence of these implies a wire-to-wire installation is possible, but I have only managed to find board-mount connectors that properly mate to the CEM-5 receptacle housing. Every inline connector that WOULD be compatible lacks the 4-pin sense connections. The best explanation I have so far is that these are hold-overs from when these parts were part of the Minitek line and haven’t been deprecated yet.

I’ve not yet researched 12V VHPWR. This is interesting. I will get to this at some point!

I am really glad I found this site – it’s nice to see an **objective** take on something like the MDPC-X crimp tool (of which I own the CT-2 (2010 ish), CTX-3, and CTX-4) aside from just Forum hobbyists.

With that said, I only recently started thinking about making custom cables for computer builds again (to cut down on excess lengths and yeah, aesthetics). Unlike my builds from the early 2000s, these are beefy “server-grade” builds (ie. $$$) with significantly higher power requirements. I am leaning towards the 63819-0900 to get those tighter crimps and avoid connector “fatigue” (this has been a problem when re-using some of my older MDPC-X crimped wires).

I like using the MDPC-X 15AWG silver wire (link: https://www.cable-sleeving.com/100m-15awg-hookup-wire-silver) or another local (read: cheaper) equivalent with the same dimensions. I’d be curious to know if you think the 63819-0900 could handle this size in the 16AWG slot? I am somewhat optimistic since you demonstrated a good result when crimping with cable sleeving. Although that only accounts for additional diameter on the insulated part, not the “thicker” conductor strands. I am also worried about the thicker conductor causing additional strain on the connector during crimping.

Really appreciate all the in-depth information on your site! Thanks.

You will get away with AWG15 wire on a Molex tool, but because the die is absolutely spot on for the specified size, the larger wire will “extrude” a little bit during crimping which will de-rate that section of the wire a tiny bit. Probably not a problem. You could mitigate it by backing off the crimp height on the tool.

I think 63819-0900 has been discontinued now. Frustratingly they replaced it with two tools, AWG16 now has its own tool.

Thanks for the quick reply! I picked up a 63819-0900 on eBay. You’re correct that there are two new tools and of course the 16 AWG model appears to be quite a bit more pricey (at least here in the US) at around $495.

It was a very informative journey reading your findings and knowledge gained over the years. I am interested in making my own custom cabling too for a new gaming rig. May somebody know that if it’s a good idea to use chinese-made silicone insulated copper wire (AWG 18, outer diameter’s around 2,7~2,8) with a CTX-4? These are IMHO reasonably well-made cables despite it’s cheapness and very-very supple.

I am planning to use them with sleeves.

Do anyone has any experience with similar cables?

Thank you for your help!